As companies across industries move toward using microtargeted marketing strategies and offering hyper-personalized products and services, medical device manufacturers, like GS Medical, have begun to incorporate this innovative concept in the production of implants and instrumentation. In recent years, manufacturing of medical devices has started to shift from traditional machining methods to the relatively new technology of 3D printing to achieve better implant design and functionality. At GS Medical we understand this push within the marketplace and we have several products, including our titanium interbody devices, currently in design of 3D printing.

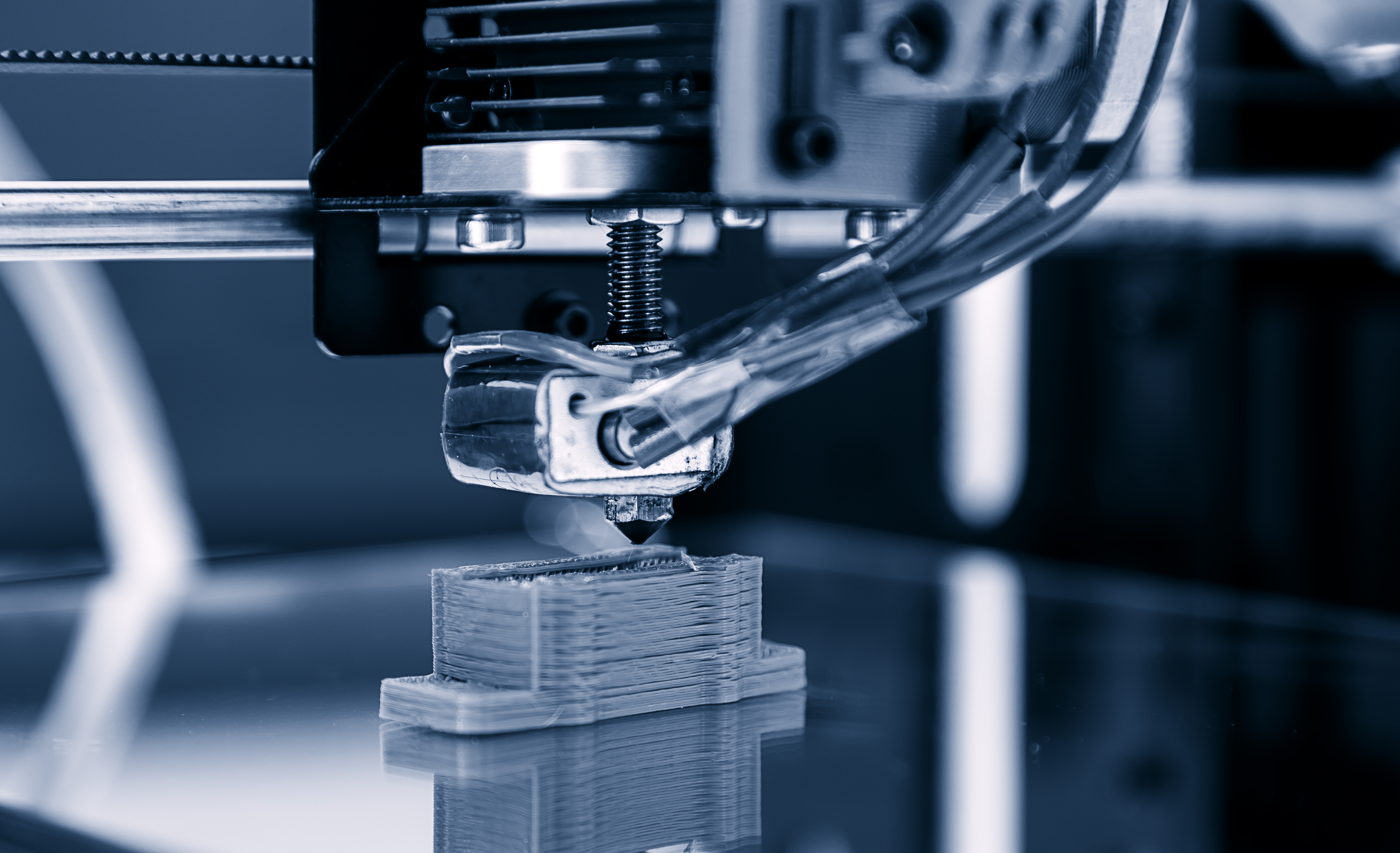

More technically referred to as additive manufacturing (AM), the 3D printing process with regard to orthopedics involves building medical devices layer by layer, allowing for increased customization and patient-specific instrumentation, as well as the engineering of more porous and complex metallic implants.

More technically referred to as additive manufacturing (AM), the 3D printing process with regard to orthopedics involves building medical devices layer by layer, allowing for increased customization and patient-specific instrumentation, as well as the engineering of more porous and complex metallic implants.

How could one expect 3D printing to impact the surgical spine industry as more and more device manufacturers begin to incorporate this revolutionary technology in the manufacturing process?

Patient-matched devices and better patient outcomes. The use of medical imaging along with 3D printing allows for the production of bespoke, implantable devices that perfectly fit with unique patient anatomy. 3D printing can also incorporate complex surface technology that facilitates bony ingrowth, resulting in improved fusion and better patient outcomes. Furthermore, 3D printing allows for the use of metal powders to produce implants that are durable, high-performing, and intricately designed, ultimately reducing the risk of implant failure.

While 3D printing of medical devices is still in a fairly nascent stage, given its capabilities, this novel technology will arguably have a profound impact on the future of medicine. It’s estimated that in 2017 roughly 340,000 implants were produced worldwide using 3D/AM technology, but by 2026 this number is expected to increase to more than 3.1 million.

The rollout of 3D printing technology in medicine, however, will likely be gradual as medical device manufacturers are held to strict regulatory standards that will require a considerable investment in the research and development of viable 3D printing processes. According to AM experts, the current best opportunity with regard to orthopedics is in standard-sized implants. However, custom devices produced to match specific patient anatomies, deformities or unique trauma are not far behind.