Key Features and Benefits

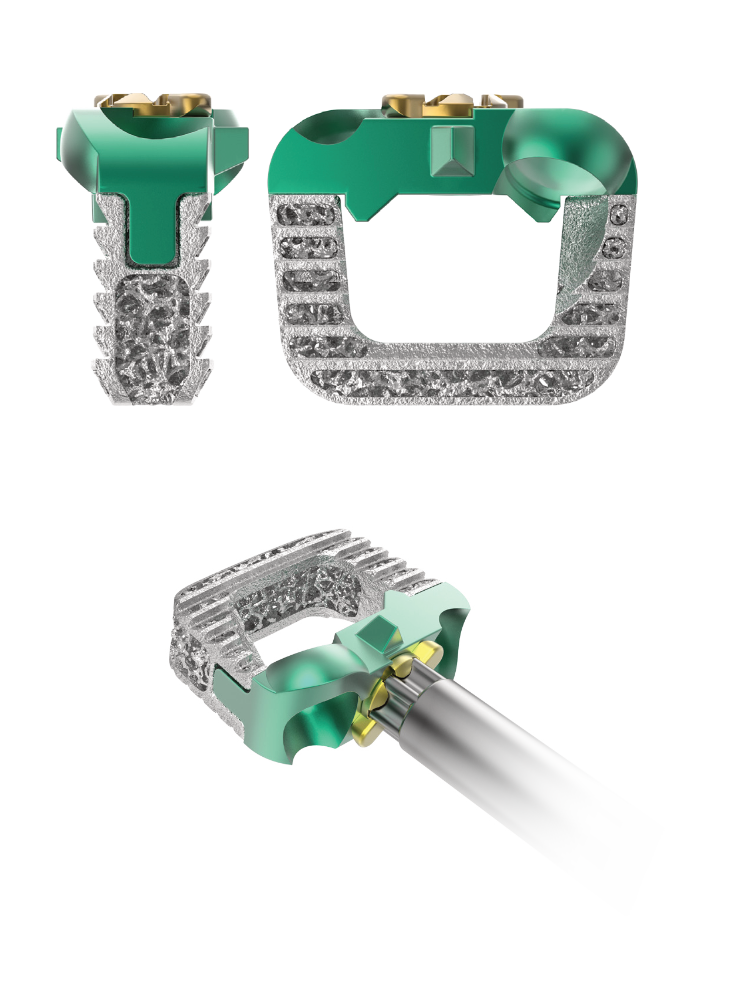

3D-Printed Titanium Technology

- Manufactured using cutting-edge 3D printing for enhanced bone ingrowth and ongrowth.

- Rough titanium surface increases osteoblast activity, promoting rapid fusion.

- Ideal 500µm pore size facilitates natural cellular influx, leading to solid bony fusion and secondary stability.

Excellent Visualization & Stability

- Implant porosity allows clear imaging, ensuring precise fusion assessment.

- Macro, micro, and nano-structured titanium promotes excellent imaging characteristics that allow the surgeon to see the fusion area clearly.

Optimized for Less Invasive Surgery

- Midline inserter placement reduces the working space required for insertion.

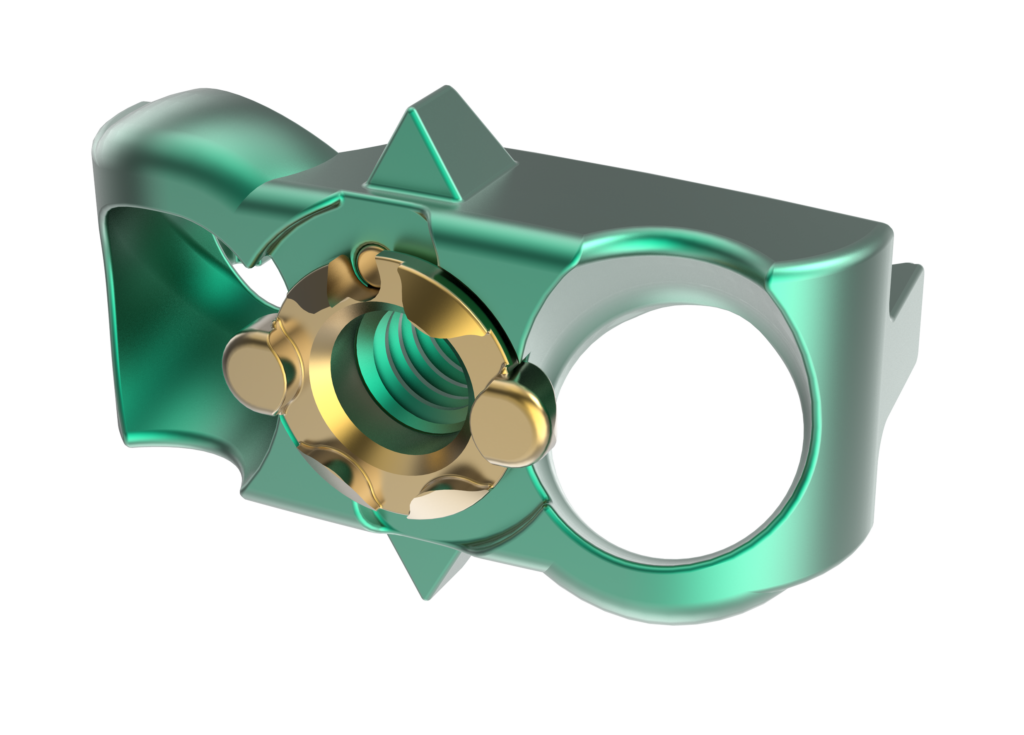

- Integrated Inserter & Locking Plate streamlines the procedure by combining cage insertion and screw locking.

Implant Overview

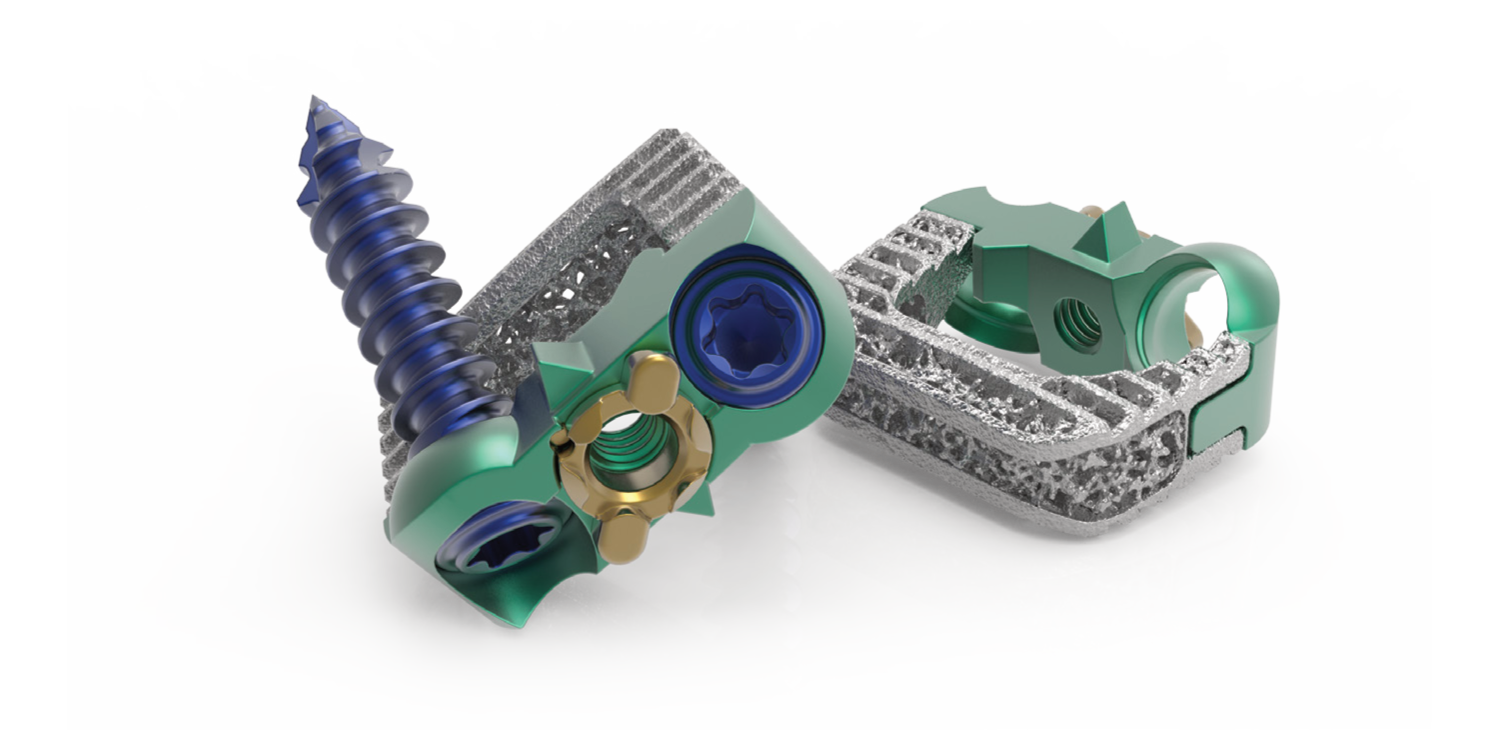

Cage

- Made from 3D-printed titanium alloy for superior bone integration.

- Three different footprint options to accommodate patient anatomy.

- Available in 5-12mm heights with 0°, 8°, and 12° lordosis for optimal sagittal alignment.

Plates

- Available Zero-Profile plate integrated with Cage seamlessly.

- Up to 36° of Cephalod/Cardal and 15° of medial/lateral screw angulation to help with optimal placement of the plate

- Low profile to minimize soft tissue irritation

Screws

- Fixed or variable angle

- Self-drilling or self-tapping

- Lengths 12 – 26 in 1mm increments

- Diameters: 3.6mm or 4.1mm

Size Options

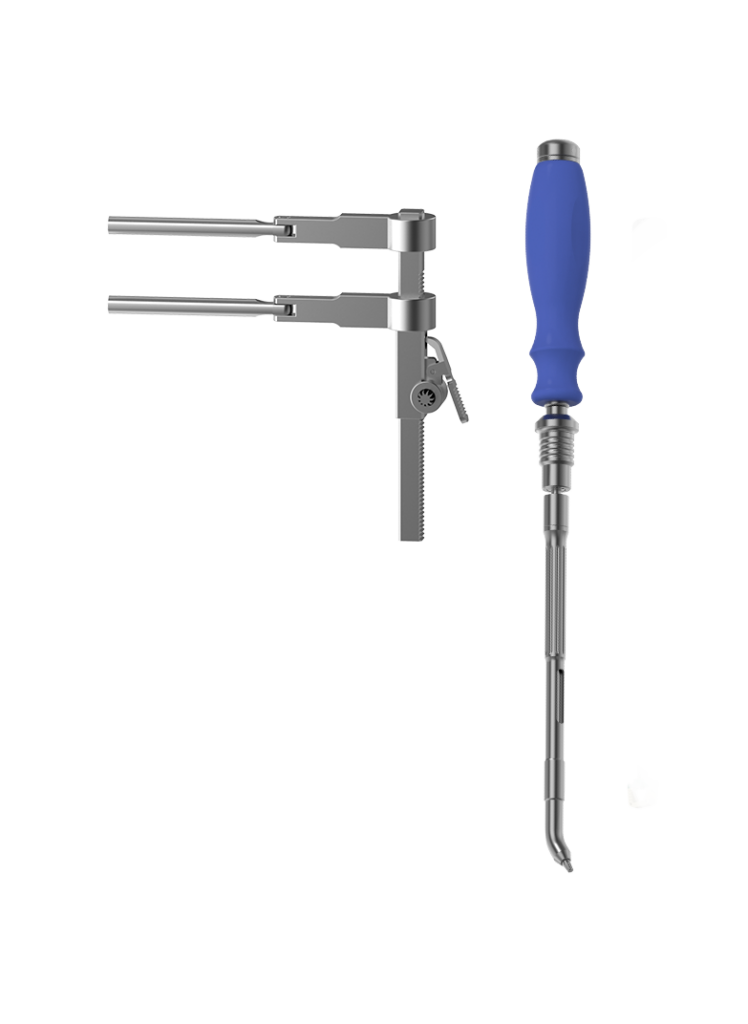

Instruments Overview

- Inserter is located in the middle of the cage and the plate construct that requires less working space during the insertion process

- Comprehensive offering of straight and angled instruments to accommodate a wide array of anatomical challenges

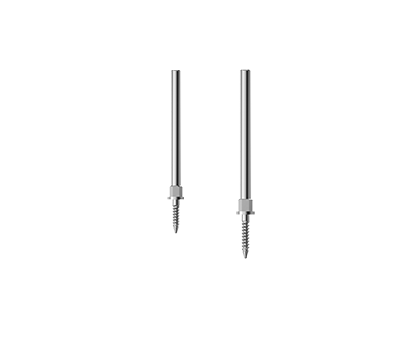

Temporary Fixation Pins

- Two different lengths of fixation pins with screws or pin/driver engagement

Subscribe GS Medical Newsletter